Nowadays heavy duty diesel engine trucks come outfitted with the most current EPA compliant equipment. That equipment comes in the form of two different methods used in the aftertreatment of the exhaust emissions. Those methods are Selective Catalytic Reduction (SCR) and increased Exhaust Gas Recirculation (EGR). Either (or both) are used to reduce NOx which is basically excess, unburned oxygen from the combustion process. In the early days, most trucks had only an EGR system with a diesel particulate filter (DPF) inline with the exhaust system so the question of SCR vs EGR was relevant. However modern diesel engines now utilise both technologies in harmony. There still seems to be a bit of confusion out there between what each system does and how they work so hopefully this article can clear things up.

Both technologies use exhaust gas recirculation to pass a certain amount of a motors’ exhaust gas back to its combustion chambers and they both make use of a diesel particulate filter (DPF). This is what removes particulate matter from the exhaust.

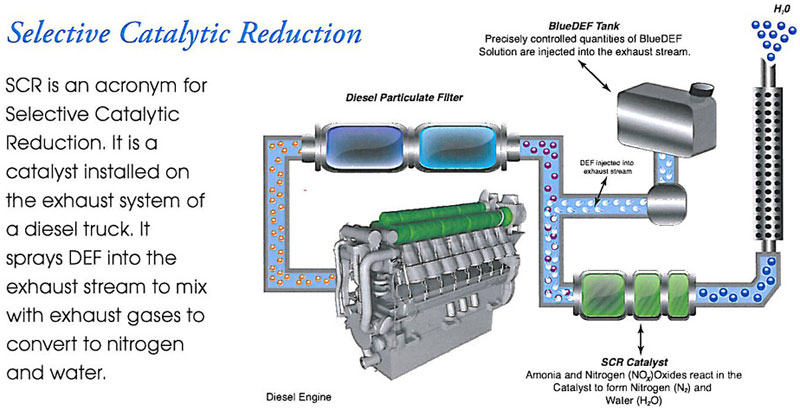

Selective Catalytic Reduction (SCR)

Lets start by explaining what SCR is. This solution allows the engine to operate under optimal combustion temperatures but that in turn produces an unacceptable amount of NOx. It is used in combination with EGR in that it does recirculate some of the exhaust gases back through the engine but only in a marginal amount. However the main treatment process of the exhaust gases is done through a chemical reaction. The exhaust gases are passed through a system called a decomposition reactor which reacts the nitrogen oxide (from the exhaust) with diesel exhaust fluid (DEF) which is most commonly a combination of de-ionized water and urea. This reaction effectively produces water and nitrogen which are environmentally safe. Notably there are two versions of the SCR technology with one using a copper zeolite catalyst and the other using an iron zeolite catalyst. Since copper zeolite is more efficient at reducing nitrogen oxide emissions, it offers a 2% increase in fuel economy. Cummins and Paccar have both implemented this version.

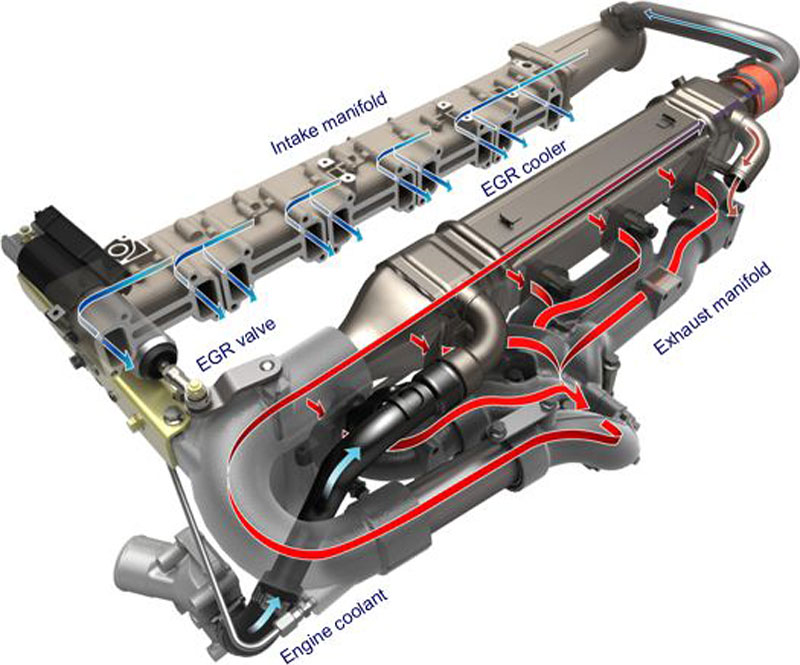

Exhaust Gas Recirculation (EGR)

Now you might be wondering what the major differences are. Well the enhanced (or increased) EGR approach works to reduce NOx by recirculating a much greater amount of exhaust back through the engines’ combustion chamber and does not make use of DEF. This exhaust gas is cooled on its way back to the engine and is mixed with oxygen rich air from the intake. Once that happens, we find a decreased amount of oxygen molecules in the combustible air because of the less oxygen-rich exhaust gas resulting in a cooler combustion temperature and reduced NOx gases. The disadvantage is that we now have a less efficient combustion process due to the lower combustion temperature which decreases fuel mileage.

Summarizing SCR & EGR

So after comparing each system, you can see that SCR does not rely on heat reduction, it relies mainly on a fluid solution from an external DEF tank to treat emissions. Additionally, enhanced EGR requires that more diesel is injected into the DPF for active regenerations – a sort of cleaning process. So what’s in it for the enhanced EGR technology? Well you don’t need to have a large DEF tank located on the truck which can end up impacting your other decisions when specifying the truck of your choice such as wheelbase and cab configuration. So if frame space is of a premium to you, don’t go with the SCR setup. SCR also adds an additional catalyst and injector along with the DEF tank which can all weigh up to several hundred pounds. Probably the most unattractive thing about an SCR system is the cost of filling up your DEF which costs anywhere from $0.80/L to $2.00/L. A truck will generally burn 40 litres of DEF every 1000-1200 kilometers.

EGR is a more simplistic approach which means less potential for things to go wrong. It uses no new technology, does not create any additional weight to the truck and does not take up valuable real estate on your truck. In addition to that, it makes no use of urea which has a known problem of availability especially at fuelling stations. So even though you may see a fuel savings of 2% with SCR, it will be negated by the cost of urea at a rate of 2-3% of diesel used.

Urea is not very stable either since it freezes at -11 degrees celsius and breaks down between 30-38 degrees celsius. So not only will the truck de-rate and shut down when the DEF (urea) tank goes empty, it will do the same thing at higher temperatures because urea loses its NOx cleaning properties when its over 30 degrees celsius. Either way, below -11 or above 30, the truck will not be meeting EPA standards and may enter limp mode.

Over the past several years, both EGR and SCR have been coming standard on all diesel trucks. So if you’re in the market for a new or newer truck you won’t have a choice. EGR by and large was implemented in 2008 and we first started seeing SCR in 2010.